You can never have too many clamps! Learn all about different types of clamps and when it's best to use each one!

If you're a DIY woodworker, you're going to have a lot of clamps around. It's one of the easiest things to accumulate over time.

Clamps are relatively inexpensive and are one tool you want in your workshop that you can reach for at a moments notice.

However, there are a lot of different types of clamps and they all serve a special purpose. That's why it's usually good to have a variety of types of clamps on hand for whatever you need.

Let's talk about 8 different types of clamps for DIY woodworking projects and what each one is best for!

Clamps for DIY woodworking projects

I've been doing DIY woodworking projects for about 10 years at this point and have been learning all along the way. That has also meant that my tool collection has grown along the way.

I started with some simple spring clamps and have grown quite a variety of clamps since then.

In this post, I'm going to explain 8 basic clamp types that are useful in DIY projects. They are organized from what I think is relatively the most basic clamp type to the slightly more specialty clamps.

There's obviously more clamps than this, but let's talk about these common ones!

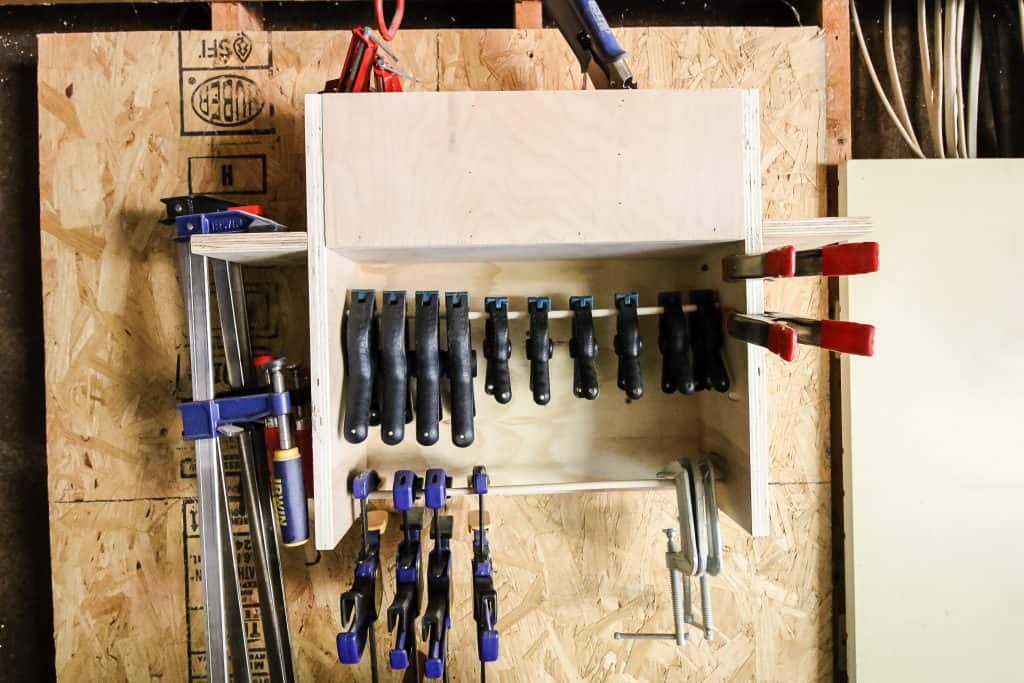

Click here to check out our DIY clamp rack we built in about an hour and holes lots of types of clamps!

Spring clamps

Spring clamps are extremely inexpensive and easy to come by. The purpose of a spring clamp is a quick and easy squeeze handle that opens two jaws and puts a mild amount of pressure on two boards.

Squeeze clamps are the easiest clamps to work, as they operate literally just by squeezing the handles and opening the jaws. These clamps are great for providing a quick clamp on two boards, which is great if you need a little pressure while glue is drying.

Spring clamps are limited though in their size, as they can only clamp boards that fit into the small opening of the jaws. But they are affordable and easy to come by.

C clamps

C clamps get their name from their C-shaped design. These clamps work by having a fixed jaw on one end and an adjustable screwed end on the other.

C clamps work by placing the wood to be clamped inside of the jaw, then turning the handle of the adjustable screw until it applies pressure to the boards on both sides.

Traditionals C clamps are great for putting direct pressure between two boards in the same point, so the clamp is straight. However, they are limited to thee space between the ends of the clamp jaws.

C clamps are also the slowest clamp to use because you have to manually spin the one adjustable end of the clamp to make it work. If you're trying to hold boards with one hand, it's not easy to use these hand screw clamps.

F clamps

F clamps are a lot like C clamps in that they are named for their shape with one moveable jaw and one that adjusts. However, unlike the C clamp that you screw, an F clamp has a sliding base on one jaw.

An F clamp functions with a base that slides on a fixed bar until it makes contact with the board, then you twist the handle to tighten it further. It gives you a wider base of contact than a C clamp and works a little better.

However, an F clamp still has the drawback that it has to be tightened by hand, so it can be hard if you're trying to hold some boards in place. But these are definitely better in my opinion.

Quick release clamps

Quick release clamps are my favorite go to clamp. These work with having two clamp faces on the jaws, one that is fixed and one that moves. To adjust the clamp, you repeatedly squeeze a trigger handle until it tightens on the boards.

I love trigger clamps because you can quickly clamp something with just one hand, a lot easier than tightening a screw like with a C clamp or F clamp. Also, you can adjust the pressure a lot easier.

Then, when you need to release the clamps, simply pull the release trigger and it pops off rapidly. In my opinion, quick release trigger clamps offer the most versatility and have a wide range of uses.

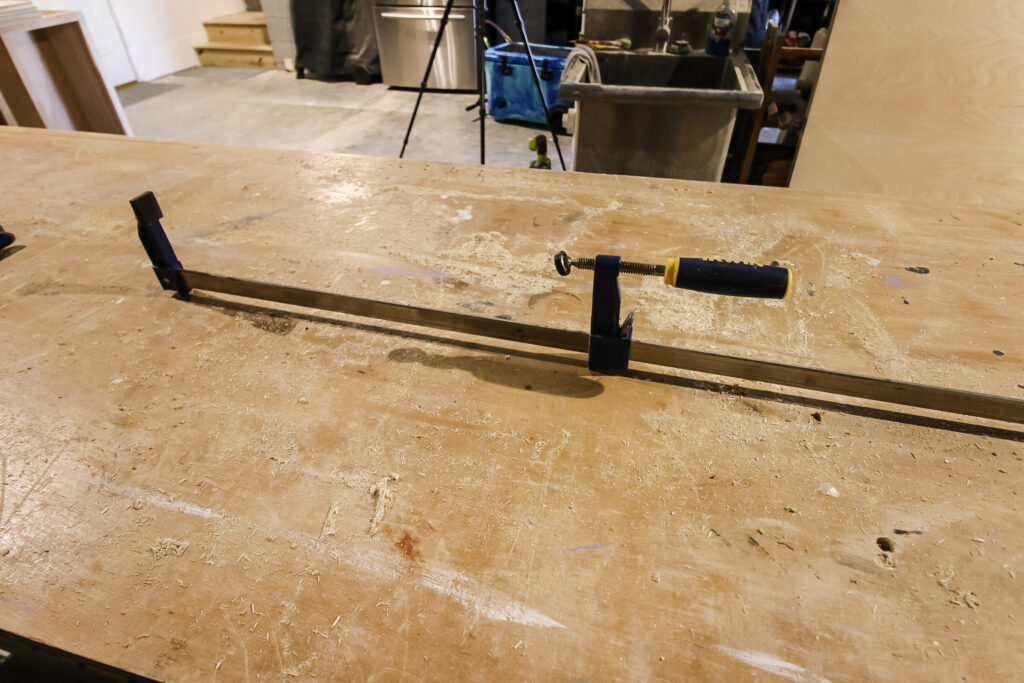

Pipe clamps or bar clamps

Pipe clamps, also known as bar clamps, are much longer than other clamps. The consist of a fixed jaw on one end and a sliding bar on the other.

Bar clamps also are capable of sitting on a workbench or the ground and staying upright, so you can load material to be clamped onto the bar and then slide the jaw to clamp.

These are great for making things like cutting boards or anything you need to stack a lot of boards together. However, they are bigger, bulkier and more expensive than any other clamps.

Right angle clamps

Right angle clamps help you to create a perfect right angle for your project. They clamp onto two boards at a 90 degree angle and keep the joint solid, which is great if you need to add nails or pocket holes.

There are several different right angle clamps you can buy. We have three different varieties actually.

- Squeeze corner clamps- these you pull back on a spring, slide the sides around the board, then release the spring to put pressure on a wedge that slides into the corner.

- Adjustable corner clamps- this are a little bigger and have to be hand tightened in place on each side, rather than happening at once. However, these are more adjustable to the size wood you need.

- 90 degree squeeze clamp- these clamps from Kreg have a fixed side that goes on the boards and a wedge that you clamp into the corner with a squeeze grip.

Bench clamps

Bench clamps are special to having on a fixed bench. Bench clamps are either fixed or slide along a rail in a work surface and only work with the bench.

There's only one side to a bench clamp as the other side is, essentially, the table itself. The clamp squeezes down onto a board on the bench and holds it in place.

These are great to have on your workbench and help minimize a need for outside clamps, but their fixed nature makes them not as versatile as other clamps.

Pocket hole clamps

Pocket hole clamps are great for helping you get a solid, flush joint when doing pocket hole projects.

A pocket hole clamp slides into an empty pocket hole, then squeezes onto the other side of the board you're attaching to. The pressure keeps the joint from moving when you are driving the screw into the hole. Once you've used it once, remove it and drive the screw in the hole you just had the clamp in.

These are good for if you do a lot of pocket hole joinery, but they can't be used for any other clamp situations.

Before you go...

Learn more about some other good tools for your workshop!

Looking for something?

We've been doing this since 2012 so we have a LOT of blog posts!

Search stuff like: Ceiling Projects | DIY Plant Stands | Thrift Flips

Hey there, I'm Sean, the woodworking enthusiast and builder behind CharlestonCrafted.com! Since 2012, I've been sharing the magic of turning raw materials into beautiful creations. I love teaching others the art and satisfaction of woodworking and DIY. I try to inspire fellow crafters to make something extraordinary out of nothing at all.