Curious about the best uses for pine wood in your next project? Whether you're crafting furniture, renovating your home, or tackling outdoor builds, find out how to make the most of this versatile and beginner-friendly wood!

When you are planning a woodworking or DIY project involving wood, one of the first things that you have to decide is what wood to use.

Boards come in a lot of different sizes, types, and species. We have a whole guide on how to buy lumber for your project!

Today I want to focus on one specific wood species: pine. Pine is a popular choice for beginner woodworking and DIY projects because it is affordable, readily available, and easy to access - it's sold almost everywhere.

But, there are some things you should know about pine before building with it. Let's take a look at everything you need to know about the best uses for pine wood!

Don't miss all of our pine articles!

Understanding Pine Wood

Pine is a soft wood that comes from an evergreen pine tree. These trees grow very quickly, making them plentiful and therefore widely available and less expensive to buy.

Because pine is so versatile, inexpensive, and easy to use, it is a popular choice for many DIYers.

However, pine can also dent and scratch easily and does not always take stain evenly. If you are looking for a super durable wood for a project that will have a lot of traffic - pine might not be for you.

Types of Pine

Pine comes in various species, each with its own characteristics that make it suitable for different uses. Here’s a closer look at some of the most common types of pine wood:

White Pine

White pine is one of the most popular and widely used species in North America. It’s known for its straight grain, smooth texture, and pale, creamy color, which can range from white to light yellow.

Workability: White pine is soft and easy to work with, making it a favorite among beginners and experienced woodworkers alike. It’s easy to cut, sand, and shape, and it takes nails and screws well without splitting.

Aesthetic Appeal: The light color of white pine makes it versatile for staining and painting, allowing woodworkers to achieve a variety of finishes. It also ages beautifully, developing a warm, honey-like patina over time.

Applications: White pine is commonly used for furniture making, cabinetry, and interior millwork, such as trim and molding. Its softness makes it ideal for projects that don’t require heavy-duty wear and tear.

Yellow Pine

Yellow pine, particularly Southern yellow pine, is known for its strength and durability. It has a distinct yellowish-brown hue and a more pronounced grain pattern compared to white pine.

Strength: Southern yellow pine is one of the strongest and hardest types of pine, making it suitable for structural applications. It’s often used in construction for framing, flooring, and heavy-duty furniture.

Density: Due to its higher density, yellow pine can be more challenging to work with compared to white pine. It requires sharper tools and more effort to cut and shape, but the results are worth it for projects requiring sturdiness.

Durability: Yellow pine is more resistant to wear and damage than white pine, making it a great choice for high-traffic areas or outdoor projects when properly treated.

Applications: This wood is frequently used for flooring, decking, fencing, and outdoor furniture. Its strength also makes it ideal for structural elements like beams and joists.

Eastern White Pine

Eastern white pine is similar to regular white pine but is specifically harvested from the eastern United States. It’s valued for its uniform texture and consistent grain, which makes it easy to work with.

Versatility: Eastern white pine is one of the most versatile types of pine, easily adapting to various woodworking techniques. It’s relatively soft, making it easy to carve and shape, but still strong enough for many types of furniture.

Aging and Patina: Over time, Eastern white pine develops a rich patina, turning from its initial light color to a deeper, golden hue, which adds character and warmth to any project.

Applications: Eastern white pine is often used in furniture making, cabinetry, and interior trim work. Its workability also makes it a popular choice for DIY projects and crafts.

Ponderosa Pine

Ponderosa pine is a large tree species native to the western United States. It’s known for its wide, straight grain and a slightly reddish tint that distinguishes it from other pines.

Workability: Ponderosa pine is moderately soft, making it easy to work with hand tools and machines. It’s known for being less resinous than other pines, which reduces the risk of sap buildup on tools.

Color and Grain: The reddish hue of Ponderosa pine, along with its wide grain, gives it a distinctive appearance that many woodworkers find appealing. It’s also a good choice for projects where the wood’s natural beauty will be highlighted.

Applications: Ponderosa pine is commonly used for doors, windows, and paneling. Its unique color and grain pattern make it a popular choice for rustic furniture and decorative items.

Choosing the Right Pine for Your Project

When selecting pine wood for your project, consider the specific needs of the project in terms of strength, appearance, and ease of work.

For structural or outdoor projects, a harder pine like yellow pine might be the best choice, while softer pines like white or sugar pine are ideal for furniture and decorative items where ease of work and finish are more important.

Best Uses for Pine Wood

You can use pine in many ways, but here are some of the most popular options:

Furniture Making

Pine can be a great option for building furniture.

Beginner-Friendly Projects: Simple projects like bookshelves, coffee tables, and side tables are perfect for pine.

Intermediate Projects: More complex pieces like bed frames, dining tables, or dressers that won't get too much surface wear and tear are great for pine, too.

We have a whole guide on how to stain pine, but remember that applying a pre-stain wood conditioner can significantly help cutting down on splotchiness or uneven absorption of stain, especially when staining darker colors!

Home Renovation

Pine can also be great for trim and other home improvement tasks.

Trim and Molding: Pine is an ideal choice for trim and molding, including baseboards, crown molding, and window or door casings, due to its smooth grain and how easy it is to work with. Its light weight allows for easy cutting, shaping, and installation, while its affordability makes it a cost-effective option for both large and small projects.

Paneling and Wainscoting: Because it is lightweight and easy to work with, pine is perfect for for wall treatments to add character to a room.

Flooring: Pine is not usually a first choice for flooring because it does. scratch so easily, but it can be a decent option in lesser-trafficked areas.

Outdoor Projects

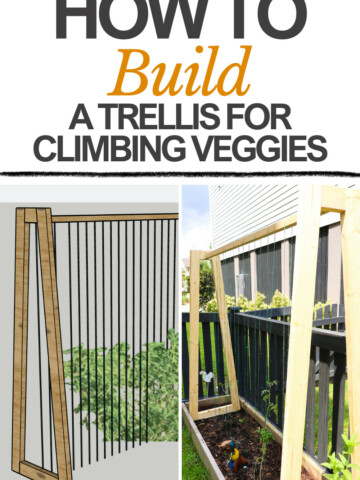

You can use pine outdoors with proper treatment. Here's our guide on how to seal pine for outdoor use!

- Garden Furniture: Build benches, planter boxes, and outdoor tables with pine.

- Decking: Use treated pine for outdoor decking and fencing.

Craft and Decorative Items

Since pine is so easy to work with, it can be great for small and beginner level projects.

Picture frames, shelves, and decorative signs are easy to make from pine.

Best Tools for Cutting, Shaping, and Sanding Pine

Cutting Pine:

- Hand Saws: Use a fine-tooth crosscut saw for clean, precise cuts without excessive tear-out along the edges.

- Power Saws: A table saw or miter saw with a high tooth count blade is ideal for producing smooth, accurate cuts.

- Jigsaws: For intricate cuts or curved shapes, a jigsaw with a fine-tooth blade offers control for detailed work.

Sanding Pine:

- Sandpaper: Start with a medium-grit sandpaper (120-150 grit) for initial smoothing, then move to a finer grit (220 grit or higher) for finishing.

- Power Sanders: An orbital sander is perfect for larger, flat surfaces, while a detail sander is useful for getting into tight corners and edges.

- Sanding Blocks: Use a sanding block for more control on flat surfaces and to avoid creating uneven areas when sanding by hand.

Avoiding Common Mistakes

Preventing Splitting:

- Pre-Drill Holes: Always pre-drill holes before driving screws or nails into pine to avoid splitting the wood, especially near edges or ends.

- Use the Right Fasteners: Choose nails or screws that are appropriate for the thickness of pine to minimize the risk of splitting.

- Avoid Excessive Force: When driving fasteners, apply steady, even pressure rather than forceful hammering or screwing to reduce the likelihood of splitting.

Avoiding Denting:

- Work on a Stable Surface: Make sure that your workbench or surface is stable to prevent the wood from moving, which can cause accidental dents.

- Handle with Care: Pine’s softness makes it susceptible to dents from drops or impacts, so handle pieces gently, especially during transportation.

- Use Protective Pads: When clamping pine, place protective pads between the clamp and the wood to distribute pressure evenly and avoid denting the surface.

Ensuring Even Staining:

- Proper Sanding: Sand the wood thoroughly before staining, starting with a medium grit and finishing with a fine grit to ensure the surface is smooth and ready to accept stain evenly.

- Use a Pre-Stain Conditioner: Applying a pre-stain wood conditioner helps to prevent blotchiness by sealing the softer areas of the pine, allowing the stain to be absorbed uniformly.

- Test Stain First: Always test your stain on a scrap piece of pine or an inconspicuous area to check how it will look before applying it to the entire project.

Safety first!

Remember to always follow safety procedures when working with power tools. That means wearing protective gear such as safety glasses, gloves, hearing protection, and dust mask and using appropriate tools to ensure safe construction.

No matter what you've heard, pine is a great wood to work with - especially for beginners. Just be aware of its limitations and tendency to dent and scratch, so you can adjust your expectations accordingly!

Looking for something?

We've been doing this since 2012 so we have a LOT of blog posts!

Search stuff like: Ceiling Projects | DIY Plant Stands | Thrift Flips

Hey there, I'm Sean, the woodworking enthusiast and builder behind CharlestonCrafted.com! Since 2012, I've been sharing the magic of turning raw materials into beautiful creations. I love teaching others the art and satisfaction of woodworking and DIY. I try to inspire fellow crafters to make something extraordinary out of nothing at all.